Exact Replica Watches

Deep Analysis Of Why Only Fake Rolex For Sale Fully Uses 904l Steel

904L steel is a stainless steel alloy with excellent corrosion resistance and is commonly used in aerospace and chemical industries. In 1985, fake Rolex for sale took the lead in using a 904L steel manufacturing steel case, relying on its high chromium content; 904l steel corrosion resistance is comparable to other precious metals, and its metal purity makes it can be highly polished. Therefore, 904L steel can bring not only incomparable bright luster but also highly durable.

Advantages of 904L steel used by fake Rolex for sale:

- First, this type of steel is more resistant to corrosion and rust than other steel types and is more robust.

- Second, 904L steel grinding out the case and chain effect is more beautiful, whether it is frosted or polished.

The difference between 904L steel and 316L steel used by Rolex:

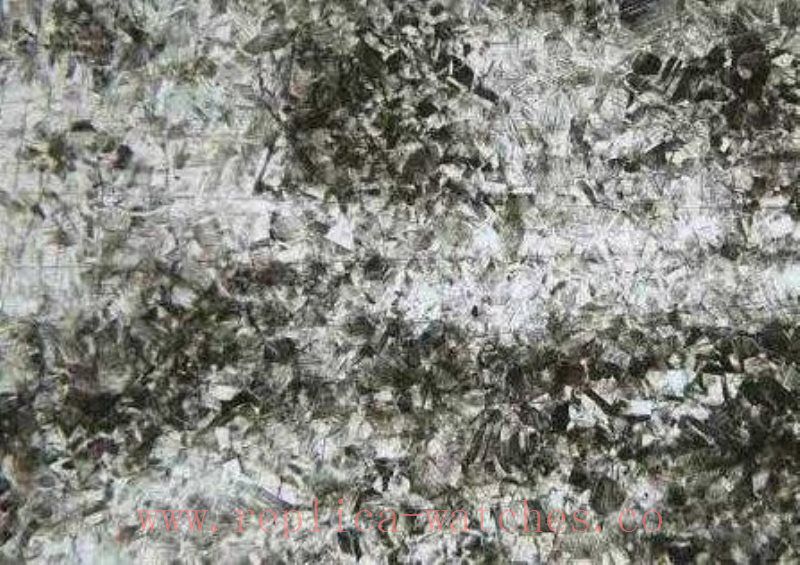

Rolex uses 904L steel. Many other Swiss watches use 316L steel, a kind of scalpel steel. It used to be very good, but fake Rolex for sale chose 904L steel to make its steel watch. It is still the only brand in the watch brand that fully adopts this steel. So what’s the difference between these two types of steel? 316L steel and 904L steel are both American names for steel grades, namely the standard steel grades of “ASTM (American Society for Testing and Material)”. The amount of carbon, silicon, manganese, and so on in the two kinds of steel is almost different. The alloy content of 904L steel (chromium, nickel, Molybdenum) is more than 1.6 times that of 316L, and the key is that 904L steel contains a certain amount of copper, but 316L does not contain copper. The Rockwell strength (HRB) of both sheets of steel is less than or equal to 95, and the power is almost 490MPa. So there’s no difference in strength or hardness. However, the higher alloy content of 904L steel and the addition of a small amount of copper make 904L steel more resistant to corrosion and wear than 316L. At the same time, 904L steel contains more Molybdenum, nickel, and copper than 316L steel, and the proportion of these three metals is more significant than iron. Therefore, in terms of weight, 904L steel with the same volume will be much heavier than 316L steel, which is more serious, and also confirms the brand temperament of Rolex — steadfast and stable.

Analysis of the excellent characteristics of 904L steel used by fake Rolex for sale:

904L steel refers to an ultra-low carbon super austenitic stainless steel, mainly used in petrochemical equipment reverberators, sulfuric acid storage, seawater disposal, etc.; it was first presented to be used in some corrosive environments, so its most important characteristic is corrosion resistance. 316L steel is a low-carbon austenitic stainless steel based on the ordinary iron matrix to participate in alloying elements. The purpose is also to prevent corrosion, but its corrosion resistance is not so strong, so it is mainly used for medical instruments or daily supplies. That is to say, 316L stainless steel is mainly used daily, while 904L stainless steel is primarily used in professional categories.

904L steel composition is mainly chromium (Cr), nickel (Ni), molybdenum (Mo), and copper (Cu), in addition to low carbon (maximum 0.02%), and silicon (Si), iron (Fe), manganese, phosphorus (P) and other elements, of which manganese (Mn) maximum 2%, chromium between 19&-23%, nickel between 23%-28%, Molybdenum in 4%-5%, copper in 1%-2%.

Of course, 904L and 316L have stainless steel in the composition of the elements are similar, but 904L has more copper, and the two practice performance is so much worse; the reason is that the element’s content is different.

Copper can effectively delay the corrosion of acidic liquid (especially chloride, the watch is the most common contact with human sweat) on stainless steel; compared with 316L, 904L increased a certain proportion of copper, improving corrosion resistance.

The content of carbon can stabilize the stability of stainless steel structure, its ability is about 30 times that of nickel, but it will produce some series of carbide and chromium; the higher the content is consumed, the more chromium will destroy the corrosion resistance of steel, which also explains why 904L steel can only have the ultra-low amount of carbon. The ratio and content of nickel-chromium can also significantly improve the corrosion resistance of the material; high nickel can make stainless steel in the active state still adhere to a meager corrosion rate, even in concentrated sulfuric acid, 904L nickel-chromium content is much higher than 316L, especially nickel, is almost twice as high as 316L.

In the daily wear of the watch, the appearance of the steel table often encountered only wear and corrosion of these two kinds of conditions, according to the 904L and 316L steel organization and composition, plus the name of drawing grinding, wear resistance has been enough, mainly corrosion. Common corrosion, especially sweat, and the electrochemical corrosion brought by humid air, if you like diving or coastal cities often contact with seawater, then the corrosion resistance of stainless steel will be higher. 904L is less prone to corrosion transformation of internal crystals (austenite to martensite) due to the stable internal structure of super austenite. At the same time, due to the advantages of super austenite in the processing technology, the welding place is not accessible to corrosion watchband section manufacturing for the welding process.

Why only Rolex exclusive full use of 904L steel:

- Sent by Rolex brand concept

Rolex is a willful brand obsessed with making imitation watches with unique specifications to make watches (fake Rolex for sale watches with different prices also enjoy unified, exceptional quality, performance, and process requirements), so there is no dispute about becoming the hegemon in the table. Rolex steel watch is also very willful, other families choose 316L steel, which is a scalpel steel, once excellent, but Rolex must choose 904L steel to do his steel watch or the current watch inside the only extensive use of this steel brand.

Anyone who knows about Rolex’s watchmaking technology will have this mystery; you will be more puzzled: fake Rolex for sale has spent enough time and body to build a rocket into space, but they are content to make a watch in the quiet.

In short, Rolex is tough. Reliability, precision, and durability are Rolex’s most shining labels. Rolex headquarters in Switzerland has several laboratories equipped with a strong research team. There were even chemists and geologists on the team. The team is “obsessed” with researching and improving all kinds of tabulation-related technologies to make high-end professional products accessible to ordinary people in their daily lives – 904L steel is only suitable for aerospace and other fields, which is not accessible to ordinary people.

- High processing difficulty and high cost

Rolex used the same type of steel as the other brands in the early days — 316L steel, but around 2003, all steel products began to use 904L steel. In 1985, fake Rolex for sale used steel 904L for the first time in the minority version of Sea-Dweller, which is more rust-resistant and corrosion-resistant. However, the 904L steel has one defect: as the hardness of the steel increases, it will be more difficult to be forged. So for 18 years, from 1985 to 2003, Rolex had to change its entire consumer line of processing equipment and tools to fully utilize 904L steel, which made sense since all their components are consumed internally. In contrast, most other brands are supplied by external suppliers. Complete the whole set of consumption line communication; this is a magnificent project and only the most capricious Rolex to do out of the money.

But the investment cost is big scary to polish more beautiful corrosion resistance better; this point is enough to make most brands prohibitive.

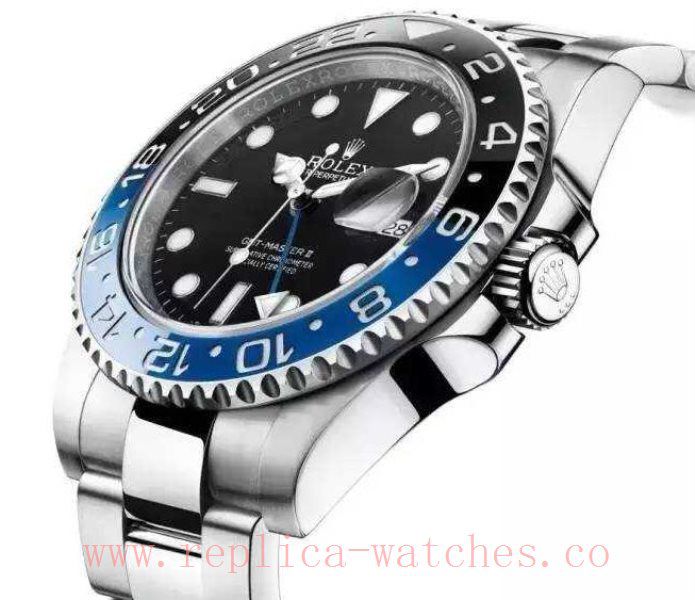

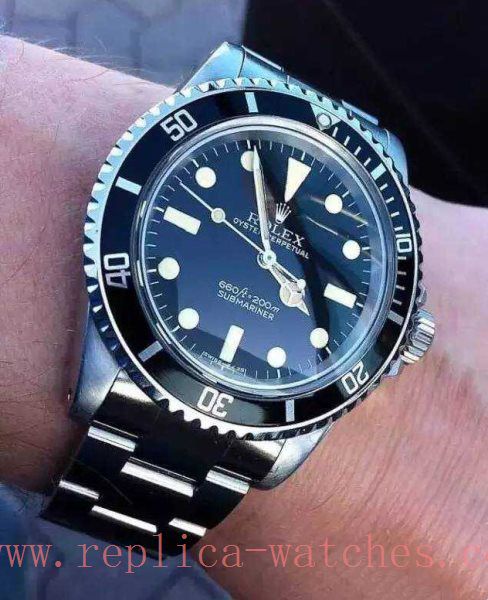

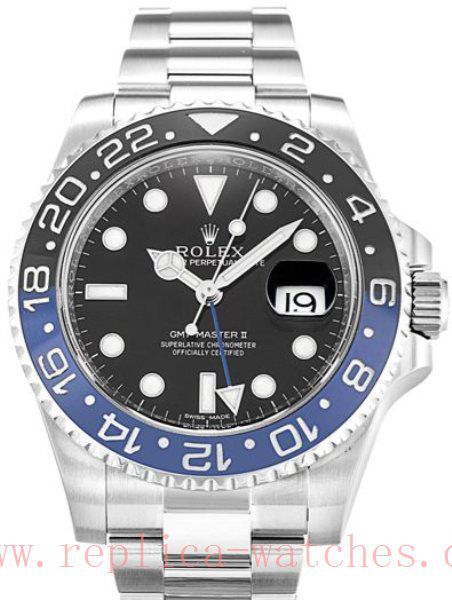

Brand:Rolex

Range:GMT Master II

Model:116710 BLNR

Gender:Mens

Movement:Automatic

Case_size:40 MM

Case_material:Steel

Bracelet_material:Steel (Oyster)

Dial_type:Black Baton

Water_resistance:Water Resistant

Detailed address: